Contact Us : +91 9820072995 / 7208483365

Managing waste is one of the biggest task for manufacturing companies.

Manufacturing facilities will often generate or utilize a significant amount of industrial waste during their day-to-day operations, and these materials have to be carefully managed in order to prevent harm to human beings and the environment. Industrial waste management is governed by numerous laws and regulations. Today’s industry practices have been developed in compliance with these rules.

Industrial Waste Disposal Methods & Restrictions

Once the waste you have utilized or generated is accurately identified, you are responsible for its proper disposal in a manner that does not violate FDA standards. There are three prohibitions that prevent hazardous waste generators from discarding waste that may damage the environment. These are-

Disposal prohibition – Requires proper treatment of the hazardous waste prior to its disposal on land.

Dilution prohibition – States that waste must be treated properly and not simply diluted by adding large amounts of water, soil, or non-hazardous materials. Dilution alone does not reduce the toxicity of hazardous waste.

Storage prohibition

This mandates that companies cannot store hazardous waste indefinitely.

Hazardous waste management is a compounded process and its disposal at regular times is mandatory.

In addition, the non hazardous waste material have also to be disposed in a proper way. For manufacturing companies, this waste is a by product in huge quantities whose regular disposal is a must.

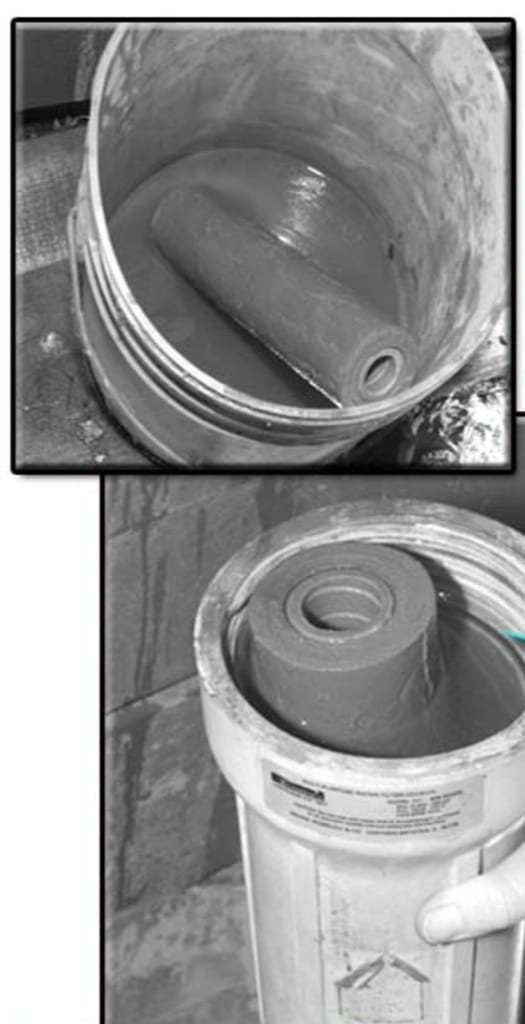

SS Filters helped Aeroflex industries pvt ltd in managing one of their non hazardous waste.

Aeroflex industries manufacture diversified stainless steel flexible hose. Originally, they were using spun filter cartridges in huge quantities to filter their material. It is a cost effective filter but one major drawback is that it cannot be reused. Hence, they were facing the problem of waste disposal. Our sales representative suggested Stainless Steel pleated filter cartridges. This had a 3 fold advantage-

After switching over to Stainless Steel pleated filter cartridges, they were very happy.

#SS Filters rules of success are simple and clear – Engage customers by understanding their problems, give quality products and seamless service.