FlowFilt Hydraulic Filter Cartridge

- FlowFilt PP Filter Cartridges

- FlowFilt Stainless Steel Filter Cartridge

- FlowFilt Membrane Absolute Filter Cartridge

- FlowFilt Microglass Fiber Filter Cartridges

- FlowFilt Capsule Filters

- FlowFilt Hydraulic Filter Cartridge

- FlowFilt Coalescent Filter Cartridge

- FlowFilt Dessicant Breather Filter

- Air Dust Collector Pleated Filter Cartridge

- FlowFilt Others

FlowFilt Hydraulic Filter Cartridge

SSFilters Pvt. Ltd. has developed number of products for lube oil, hydraulic oil & replacement filter elements. Contamination is the number one cause of failure in hydraulic & lubrication systems. Failures can cause down time, component & fluid replacements as well as higher maintenance expenses. SS Filters Pvt. Ltd. hydraulic filter deliver positive protection against contamination giving you predictable reliability for your fluid power equipment.

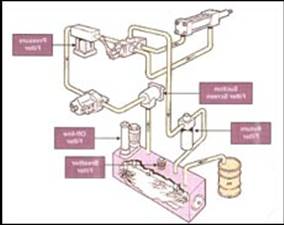

It is very important to select a filter that will improve the reliability of a lube or hydraulic system so that the cost of any failure is not due to contamination. Filters are named according to their location in a lube or hydraulic system.

Accordingly we have:

- Suction Filter.

- Pressure Filter.

- Return Filter.

- Offline Filter.

- Breather Filter.

Suction Filter

This filter is located on a suction port of the pump or submerged in the reservoir and attached to the suction line leading to the pump. The main function of the suction filter is to protect the pump from large particles found in the reservoir. This filter is usually a coarse mesh filter or even a magnetic separator. High efficiency filters are usually not placed on the suction side as high differential pressure can cause pump failure.

Pressure Filter

This filter is generally inserted between the pump outlet & the rest of the components in a hydraulic system. The idea here is to protect all components is a given system. This filter must withstand full system pressure & must be capable of handling the maximum flow of the pump including pressure cycles & fluctuating flow pressure. In most cases this is usually the smallest filter but also the most expensive.

Filter with a bypass utilize element that are classified as low collapse (can withstand differential pressure upto 450 psid, 30 bar.) Filter with no bypass utilize element that are classified as high collapse (can withstand differential pressure upto 3000 psid, 450 bar.)

Return Filter

Return filter may be installed either in-line or inside the reservoir. The designer of the system collects all flow from the system and directs it through the return line filter so that the oil in the reservoir will beclean.

Return filters are fitted with internal or external by pass valves as a standard since they are subject to flow rates that may be higher than that of maximum pump flow rate. The by-pass valve protects the housing from bursting & the element from collapse failure. Over sizing the return filter is a common practice. This allows the flexibility to enhance the degree of filtration without creating excessively high differential pressure. Normally this is the largest & the least expensive filter and a common filter for a mobile hydraulic system.

OfflineFilter:(Dedicated)

Some OEMS or the users of a hydraulic or lube system install an offline filter system. This system is a self contained filter system. It includes a pump-motor combination as a power source and a range of filtration flexibility to achieve many desired results. It can easily be connected to a system reservoir. This system can be run 24/7 or intermittently.

High efficiency breathers can extend the life of all filter elements on hydraulic & lubricating system by controlling airborne ingression, which is one of the major sources of particulate contamination. Spin-on & desiccant breathers come in a wide range of adaptors so that any reservoir or gearbox can be retrofitted.

SS Filters Pvt. Ltd. provide high quality replacement hydraulic & fuel oil filters to meet the increased performance demands of today’s hydraulic systems including cartridges, spin-ons, breathers, in-line filter, pressure filter, suction filter & off-line filters.

We can help you choose the filter that will meet all your requirements for cleanliness, high capacity, performance, reliability, filter life & economy.

Medias to meet specific Applications:

We offer four filter medias which offer the optimum reliability in wide range of temperatures with retention rates from 1 to 200 microns. This enables you to choose the media that is most effective for your specific application.

- Cellulose is an inexpensive media suited for light duty applications.

- Microglass has much better dirt holding capacity & can last up to 4 to 5 times longer than cellulose. It provides the ultimate cleanliness & has superior fluid compatibility with hydraulic fluids, synthetics, solvents & high water based fluids. Improved fluid cleanliness provides more reliable equipment, less down time & reduced equipment maintenance cost.

- Water removal micro-glass has the same feature as our Micro-glass media but offers the advantages of removing small trace of water which significantly increases performance & equipment in hydraulic & lube systems.

- Stainless wire mesh is a washable media which is suitable for heavy duty application with higher micron retention rates.