Cooling Tower

Cooling Tower

What is a cooling tower?

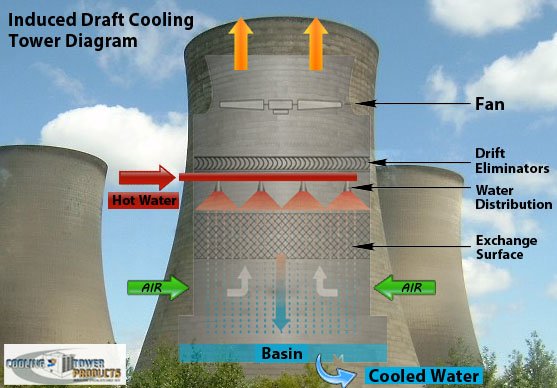

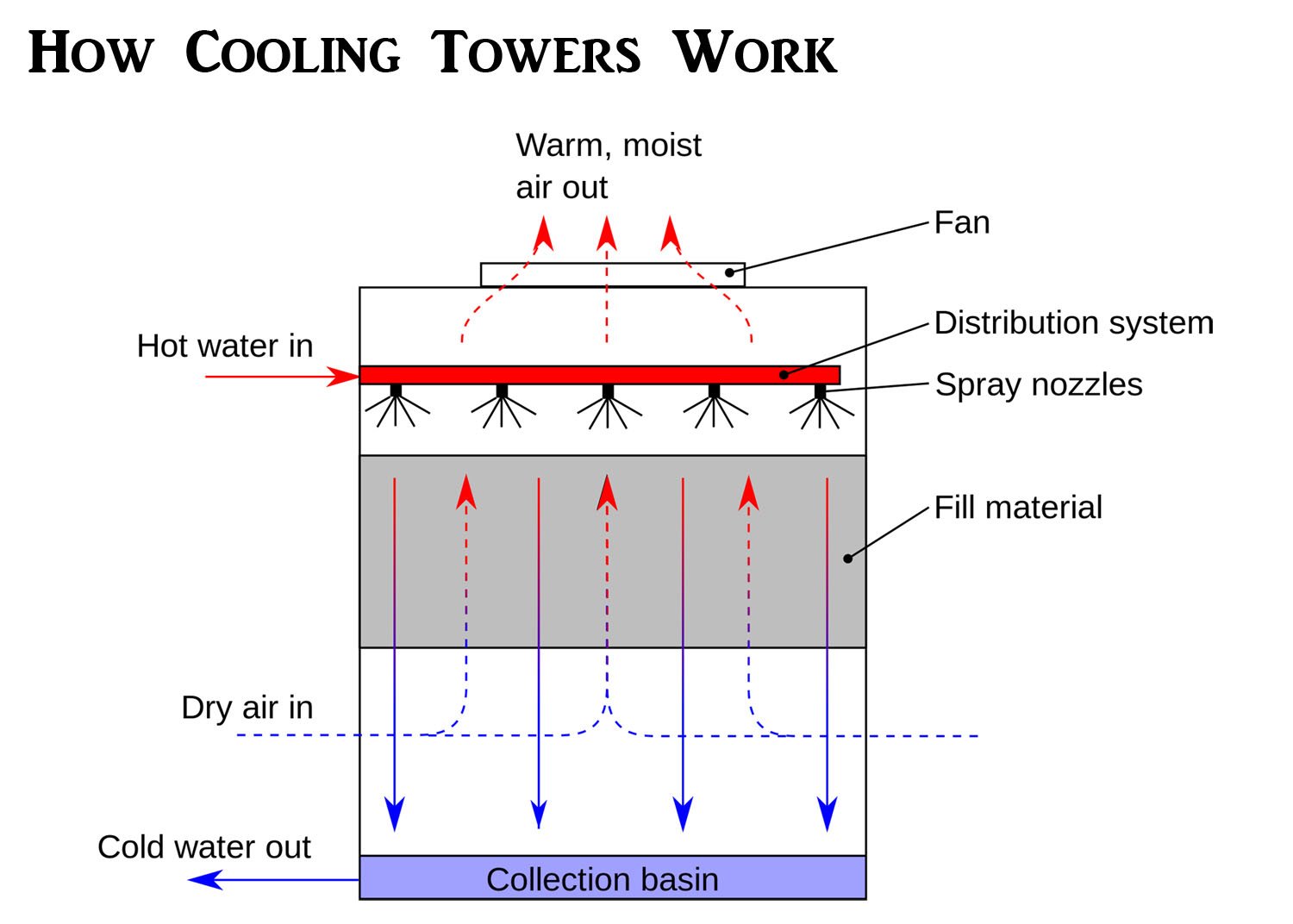

Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water.

In a short summary, the purpose of a cooling tower is to cool down water that gets heated up by industrial equipment and processes. Water comes in the cooling tower hot (from industrial process) and goes out of the cooling tower cold (back into the industrial process).

Principle of Cooling Tower

The hot water is usually caused by air conditioning condensers or other industrial processes. That water is pumped through pipes directly into the cooling tower. Cooling tower nozzles are used to spray the water onto to the “fill media”, which slows the water flow down and exposes the maximum amount of water surface area possible for the best air-water contact. The water is exposed to air as it flows throughout the cooling tower. During the process, small volumes of water evaporate, lowering the temperature of the water that’s being circulated throughout the cooling tower. The air is being pulled by an motor-driven electric “cooling tower fan”.

What is an HVAC System?

An HVAC (Heating, Ventilation and air conditioning system) is responsible for heating and cooling your home and includes products like furnaces, air conditioners, heat pumps as well as ductwork, thermostats and other home comfort controls. Traditional HVAC heating and cooling systems are used in schools, large office buildings, and hospital.

Applications of Cooling Towers

Cooling towers are much larger than traditional HVAC systems and are used to remove heat from cooling tower water systems in petroleum refineries, plants, natural gas processing plants, petrochemical plants, and other industrial processes.

In my earlier post, I had explained about cooling towers, working, principle and its applications. During the process of cooling towers, the water has to be filtered because in the cycle it carries solid particles which will harm the condenser, evaporators and all parts of machinery coming in contact with dirty water.

Case Study:

Our sales engineer received an enquiry where dirty water had to be cleaned in cooling tower. Clean water is important in cooling towers.

Water in the cooling towers can be cleaned by offline filtration system or online filtration system.

Offline filtration system with pump

We suggested single basket strainer filter of 10 micron with housing and pump. This system is separately attached with the tank containing the water. It can be attached at any place in the system. The water after leaving the tank is filtered and put back in the tank. This can be used if the water is not very dirty or if filtration is required separately without disturbing the actual process of cooling tower.

Online filtration system

Generally, online filters are used. According to the solid load, we suggest a basket strainer or a bag filter housing in a duplex filter system. In this process, water after it leaves the water tank, gets filtered before it reaches the cooling towers. Normally an online duplex strainer is used. There is continuous flow and the line does not have to be stopped to change or clean the filters. One chamber of the duplex filter is always in a filtering mode and the other is always with a cleaned filter element offline. So if inline filter gets choked, with a change in direction of the valve, the other filter can be used as the inline filter.

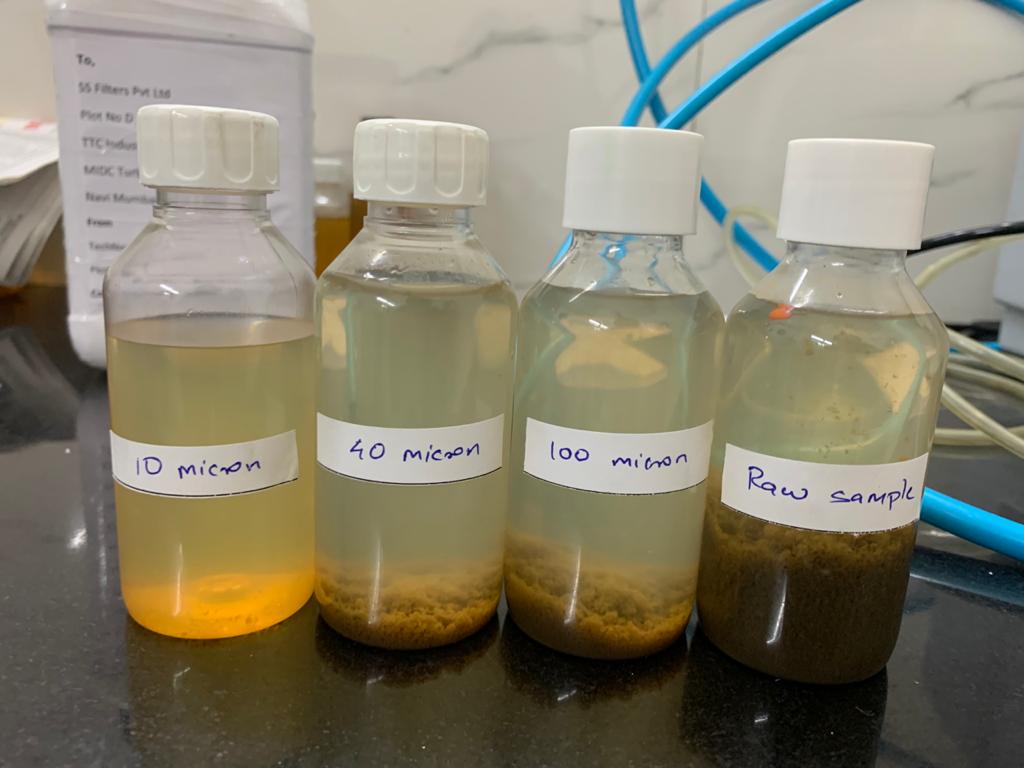

We had conducted various tests with the water sample of HFCL Ltd. Below are the test results of unfiltered water in the cooling tower, and filtered water after filtering at different micron ratings.